Nitric Acid & Nitrates

Commercial Nitric Acid Production

The problem with the current process:

The Ostwald process consumes much of the fossil-fuel energy in ammonia when it is oxidised into Nitric Acid due to the need for high temperatures (850-900°C) and high pressures (4-10 atm).

These process conditions also make the process centralised, CAPEX heavy, and continuous operation makes it difficult to decouple from fossil fuel derived ammonia production whilst also consuming expensive metal catalysts.

We’re changing the future of nitric acid production

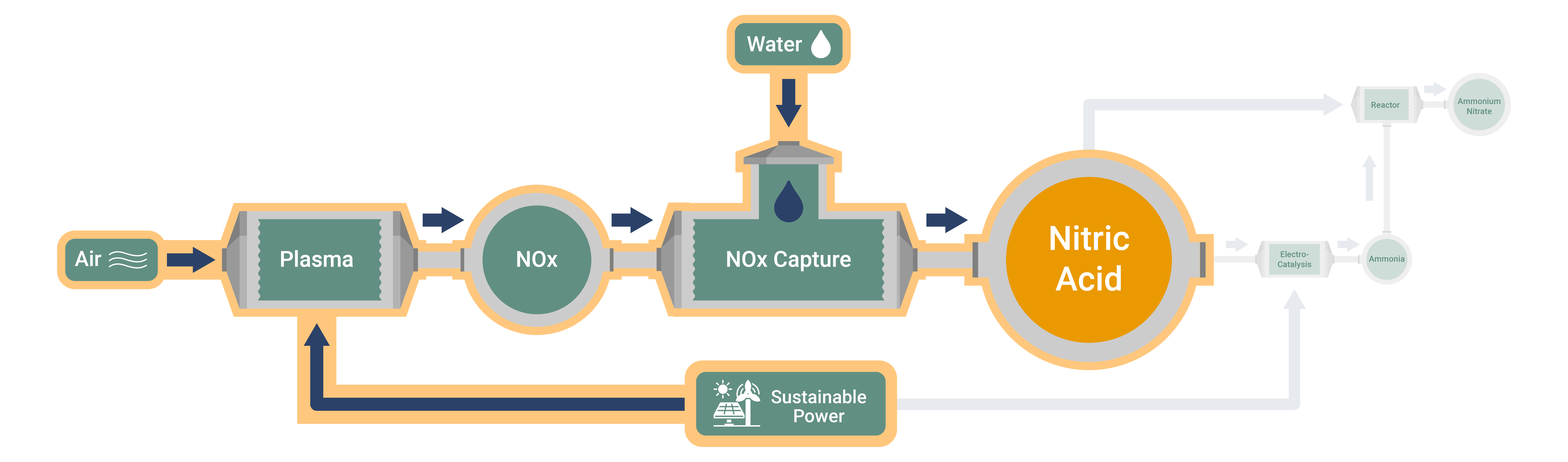

Streamlined Nitric Acid Production

Our plasma process simplifies the pathway to nitric acid by avoiding using ammonia as a feedstock.

Decoupling of Ammonia and Nitric Acid Production

Traditional production via the Ostwald process requires ammonia as feedstock for nitric acid production. Our process allows ammonia and nitric acid to be produced independently, increasing flexibility.

Cheaper Nitric Acid Production

Our plasma reactor does not require expensive metal catalysts and operates at room temperature and atmospheric pressure. Since the specific CAPEX is lower, the overall production cost is reduced, making the levelized cost of nitric acid from our reactor, at current performance levels, competitive with traditional fossil fuel-based processes.

Decentralised

Our process can be operated at small scales making onsite production of nitric acid a realistic option.

Our sustainable Nitric Acid production process